For wholesalers, real estate developers, and bathroom contractors, selecting a shower enclosure manufacturer is not just about finding a supplier—it is about choosing a long-term strategic partner. A high-quality enclosure defines the safety, aesthetics, and longevity of a bathroom project.

With the global market saturated with options, how do you distinguish a professional manufacturer from a middleman? This guide explores the critical benchmarks from an industry perspective to help you make an informed procurement decision.

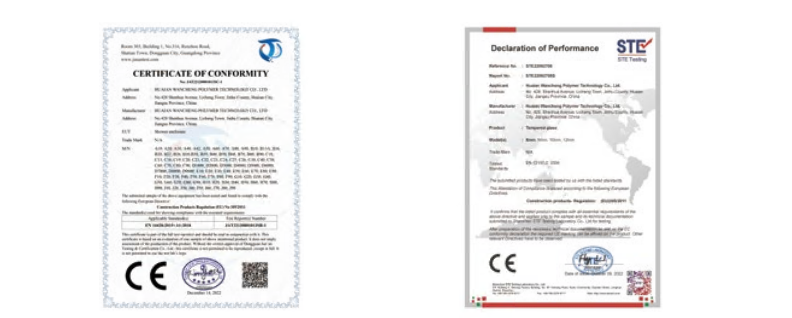

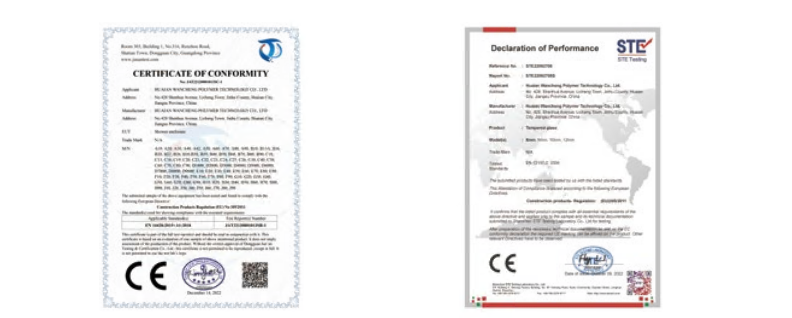

1. Safety First: Glass Standards and Certifications

In the sanitary ware industry, glass safety is non-negotiable. For the European market, a reputable manufacturer must comply with the

EN 12150-1 standard (the European standard for thermally toughened soda lime silicate safety glass).

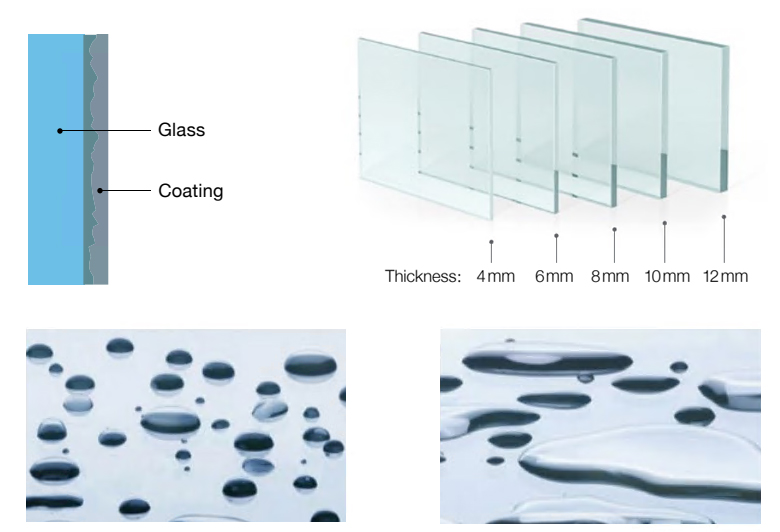

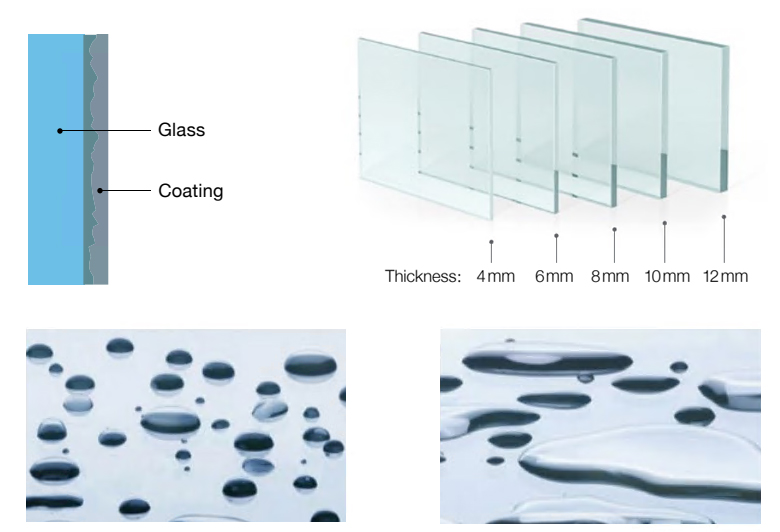

- Tempered Excellence: Look for glass that has undergone rigorous tempering processes, making it 4–5 times stronger than standard glass.

- Easy-Clean Technology: Modern projects demand low maintenance. Professional manufacturers often apply an "Enduro" or "Easy Clean" nano-coating that repels water and prevents limescale buildup.

- Thickness Options: Depending on the project (e.g., luxury hotels vs. standard apartments), you should have access to 6mm, 8mm, or 10mm options.

Expert Tip: Always verify the manufacturer's CE and ISO certifications to ensure compliance with international safety and quality management systems.

2. Design Flexibility and Customization (OEM/ODM)

A "one size fits all" approach rarely works in high-end bathroom design. A manufacturer’s ability to provide

custom shower enclosures is a testament to their technical depth.

- Opening Types: A versatile supplier should offer a full range of solutions, including Sliding doors (ideal for space-saving), Pivot/Hinged doors (for a classic feel), and Walk-in screens (for modern, minimalist aesthetics).

- Profile Finishes: Beyond standard Polished Chrome, professional manufacturers stay ahead of trends by offering finishes like Matt Black, Brushed Gold, and Gunmetal to match contemporary bathroom hardware.

- Dimensional Accuracy: For large-scale construction, the ability to manufacture "Made-to-Measure" sizes is critical for seamless installation.

3. Manufacturing Scale and Supply Chain Stability

For B2B buyers, lead times and production capacity are vital for project ROI. A manufacturer with a proven track record (ideally 20+ years) and a significant factory footprint (upwards of 40,000 m²) indicates a stable supply chain.

- Production Capacity: Can the factory handle 20,000+ units per month? This ensures they can scale with your business growth.

- In-house Production: Manufacturers that produce their own tempered glass or aluminum profiles in-house have better control over quality and cost, which translates to more competitive wholesale pricing for you.

4. Hardware Durability: The Hidden Details

The longevity of a shower room is often determined by its hardware, not just the glass.

- Aluminum Profiles: High-purity aluminum (approx. 99%) ensures corrosion resistance, especially in humid bathroom environments.

- Rollers and Hinges: In sliding systems, double rollers made of stainless steel or high-grade brass ensure a "soft-close" feel and thousands of smooth cycles without failure.

5. Technical Support and B2B Packaging

A manufacturer’s responsibility shouldn't end when the goods leave the factory. Evaluation should include:

- Installation Support: Detailed manuals, and technical drawings are essential for contractors on-site.

- Export-Grade Packaging: For international shipping, look for 5-layer corrugated cartons with EPE foam protection and palletized shipping to minimize breakage rates during transit.

- Warranty: A reliable manufacturer will offer a comprehensive warranty (usually 2-5 years) on hardware and glass, reflecting confidence in their craftsmanship.

Conclusion

Choosing the right

shower enclosure manufacturer requires balancing technical expertise, safety compliance, and production scale. By focusing on certified safety glass, customization capabilities, and a proven industry track record, B2B buyers can secure products that enhance their brand reputation and project value.

At

Daya Sani-Ware, we leverage 25 years of manufacturing expertise and a 48,000m² production base to deliver CE-certified shower solutions to 60+ countries. Whether you are sourcing for a boutique hotel or a wholesale distribution network, our team is ready to provide the technical support your project deserves.